The Cornerstone of Modern Manufacturing: Precision CNC Machining Company

In today's rapidly evolving industrial landscape, the role of a precision CNC machining company cannot be overstated. These companies utilize advanced technology to produce high-quality components with unparalleled accuracy and efficiency. This article will delve deep into the significance of precision CNC machining, its benefits, and its impact on the metal fabrication industry, especially highlighting the expertise of deepmould.net.

Understanding CNC Machining

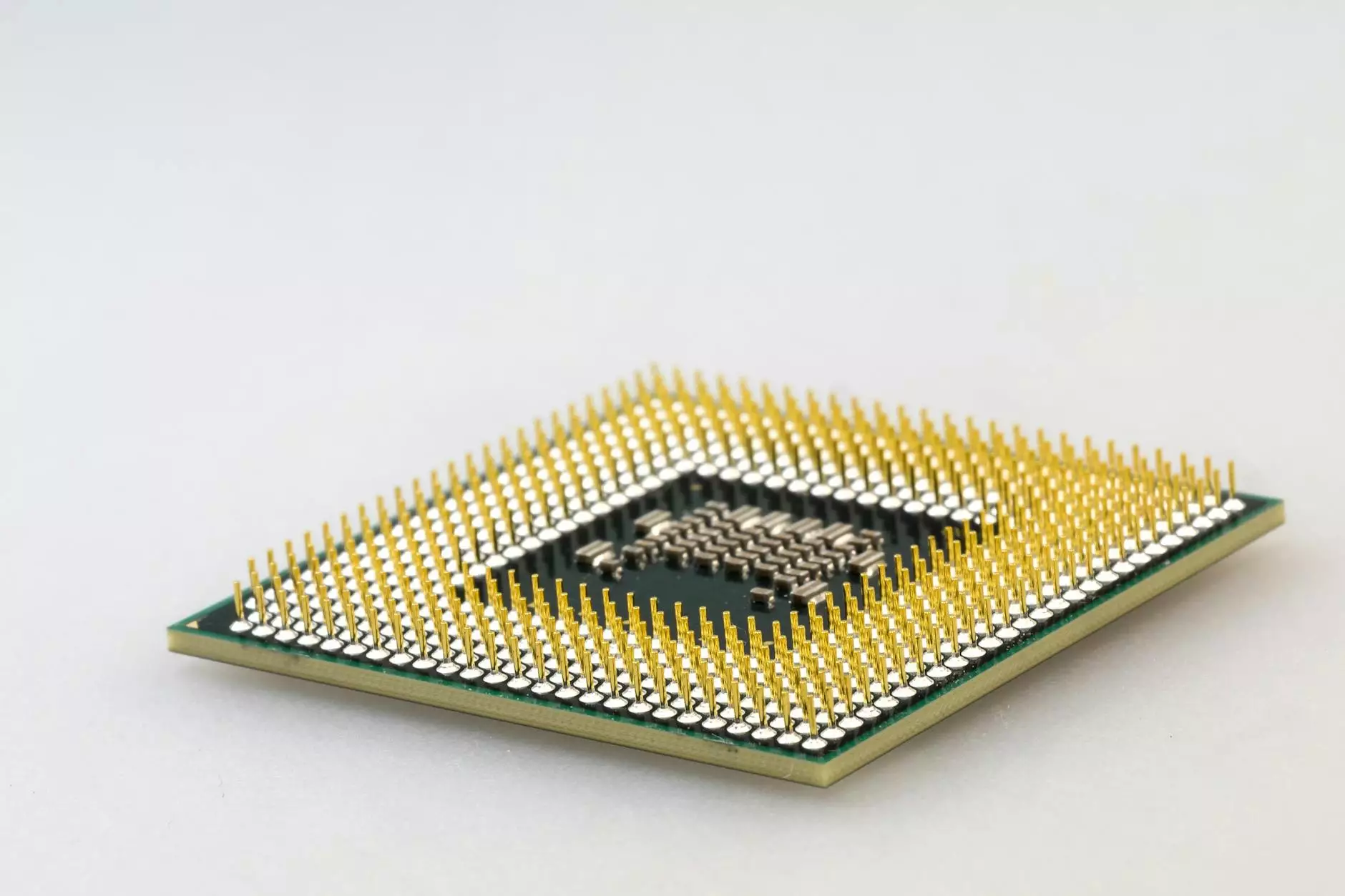

CNC, or Computer Numerical Control, machining is a manufacturing process that utilizes pre-programmed computer software to dictate the movement of production equipment. This technology is widely used in manufacturing processes, particularly for metal fabrication. The precision CNC machining company harnesses this technology to produce both complex and simple parts with consistent precision.

The Process of CNC Machining

The CNC machining process is methodical and intricate. Here’s a detailed overview:

- Design Creation: The journey begins with the creation of a digital design using CAD (Computer-Aided Design) software.

- Programming: Once the design is complete, it is converted into a CNC program that instructs the machine on how to create the part.

- Machine Setup: The machine is then set up with the correct tools and materials, ready to execute the program.

- Production: The CNC machine begins the manufacturing process, cutting, shaping, and finishing the metal as per the specifications.

- Quality Control: After production, the parts undergo rigorous quality checks to ensure they meet the required standards.

Advantages of Choosing a Precision CNC Machining Company

Opting for services from a precision CNC machining company offers myriad advantages:

- Unmatched Precision: CNC machining can produce parts with tolerances as tight as ±0.001 inches, ensuring a high level of accuracy.

- Efficiency: The automated nature of CNC machining allows for high-volume production while significantly reducing lead times.

- Variety of Materials: CNC machines can work with a wide array of materials, including steel, aluminum, plastics, and more.

- Complex Designs: CNC technology allows for the creation of intricate designs that would be nearly impossible to achieve with traditional methods.

- Reduced Waste: The precision of CNC machining minimizes material waste, contributing to cost efficiency and environmental sustainability.

The Role of Metal Fabricators

Metal fabricators play a crucial role in the manufacturing cycle. They are responsible for transforming raw metal into functional components through various processes, including:

- Welding: Joining metal parts together through the application of heat and pressure.

- Cutting: Using saws or laser systems to accurately trim materials to required dimensions.

- Forming: Shaping metal components through processes such as bending or stretching.

A precision CNC machining company integrates post-fabrication processes, enhancing the value of metal fabrication services.

Innovations in CNC Machining Technology

As technology progresses, CNC machining continues to innovate. Some of the latest advancements include:

- Multifunctional Machines: These machines can perform multiple operations such as milling, turning, and drilling in one setup, dramatically increasing efficiency.

- Automated Quality Control: Incorporating sensors and software that automatically check and adjust tolerances during the production process.

- 3D Printing Integration: Combining CNC machining with 3D printing to enhance the production of complex parts.

- IoT Connectivity: Leveraging the Internet of Things (IoT) for real-time monitoring and optimization of the machining processes.

Choosing the Right Precision CNC Machining Company

When selecting a precision CNC machining company, consider the following criteria to ensure you make an informed decision:

- Experience: Look for a company with a proven track record in CNC machining and metal fabrication.

- Technology: Ensure they use advanced machining technology that can meet your specific manufacturing needs.

- Quality Assurance: Check for quality certifications and the presence of a robust quality control system.

- Customer Service: Choose a company that values communication and offers responsive customer service throughout your project.

The Future of Precision CNC Machining

The future of precision CNC machining appears bright, with ongoing advancements bolstering its capabilities. As industries continue to demand more complex and precise parts, CNC technology will evolve, incorporating state-of-the-art innovations that drive efficiency and reduce costs. Companies like DeepMould are at the forefront of this evolution, setting new standards in the metal fabrication industry.

Conclusion

A precision CNC machining company is essential in modern manufacturing, specifically in metal fabrication. Its meticulous processes, advanced technologies, and the ability to produce high-quality components make it indispensable. As industries grow and technology advances, the role of these companies will expand, offering unprecedented opportunities for innovation and growth. For those in need of expertise and quality in metal fabrication, a reliable partner like DeepMould could be the key to unlocking success.

Contact Us

To learn more about our services and how we can assist you with your precision CNC machining needs, visit DeepMould or reach out to our team of experts today!