The Comprehensive Guide to Label Printer Applicators

In today's fast-paced business environment, label printer applicators play a crucial role in enhancing operational efficiency and meeting labeling demands across various industries. From manufacturing to retail, these sophisticated devices streamline the labeling process, reduce manual labor, and ensure high-quality results. This article delves into the workings, benefits, and advancements in label printer applicators, positioning OmegaBrand.com as your go-to source for all your printing service needs.

What is a Label Printer Applicator?

A label printer applicator is an automated device designed to apply labels onto products, packaging, or surfaces with precision and speed. These machines come in various types, each tailored to different applications, including:

- Inline Applicators: Perfect for high-speed assembly lines.

- Random Case Applicators: Allow for label application on items of varying sizes.

- Handheld Applicators: Portable options suitable for smaller tasks or locations.

How Do Label Printer Applicators Work?

The operation of a label printer applicator can be broken down into several key steps:

- Printing: Labels are printed on demand using thermal transfer or direct thermal printing technologies.

- Dispensing: The printed label is automatically dispensed from the roll or sheet.

- Application: Using technology such as pneumatic or electric arms, the label is carefully applied to the designated product or packaging.

Key Benefits of Using Label Printer Applicators

Integrating label printer applicators into your business processes can yield a multitude of benefits:

1. Increased Efficiency

Manual labeling processes are often time-consuming and prone to human error. Label printer applicators significantly reduce labor hours by automating the application process, allowing employees to focus on more critical tasks.

2. Consistency and Quality

The accuracy of label placement is paramount, especially in industries like food and pharmaceuticals, where compliance is essential. Label printer applicators ensure that each label is placed consistently and accurately, enhancing product presentation and meeting regulatory requirements.

3. Cost Savings

While the initial investment in a label printer applicator may be considerable, the long-term savings realized through reduced labor costs and increased productivity can be substantial.

4. Versatility

Modern label printer applicators are designed to handle various label sizes, types, and materials, making them suitable for a wide range of products and industries.

Applications of Label Printer Applicators

Label printer applicators find use in diverse sectors, including:

- Manufacturing: For labeling products ready for shipment, ensuring traceability.

- Retail: For automatic pricing and promotional labels on the sales floor.

- Logistics: For packaging and shipping labels that enhance clarity and efficiency in distribution.

- Food & Beverage: For compliance with labeling regulations and maintaining quality standards.

- Pharmaceuticals: For accurate and compliant labeling of medicines and health products.

Choosing the Right Label Printer Applicator

When selecting a label printer applicator, consider the following factors to ensure you choose the right fit for your business:

1. Application Type

Determine whether you need an inline system for high-volume production or a more flexible option for varied product sizes.

2. Printing Technology

A comparison of printing technologies like thermal transfer and direct thermal will help you understand the best options for your labeling needs.

3. Speed Requirements

Assess the speed at which labels need to be applied to keep up with production demands.

4. Label Material Compatibility

Ensure that the applicator can handle the type of labels you plan to use, whether they are paper, plastic, or specialized materials.

Innovations in Label Printer Applicators

The landscape of label printer applicators is continuously evolving, with technology paving the way for improved functionality and efficiency. Some recent innovations include:

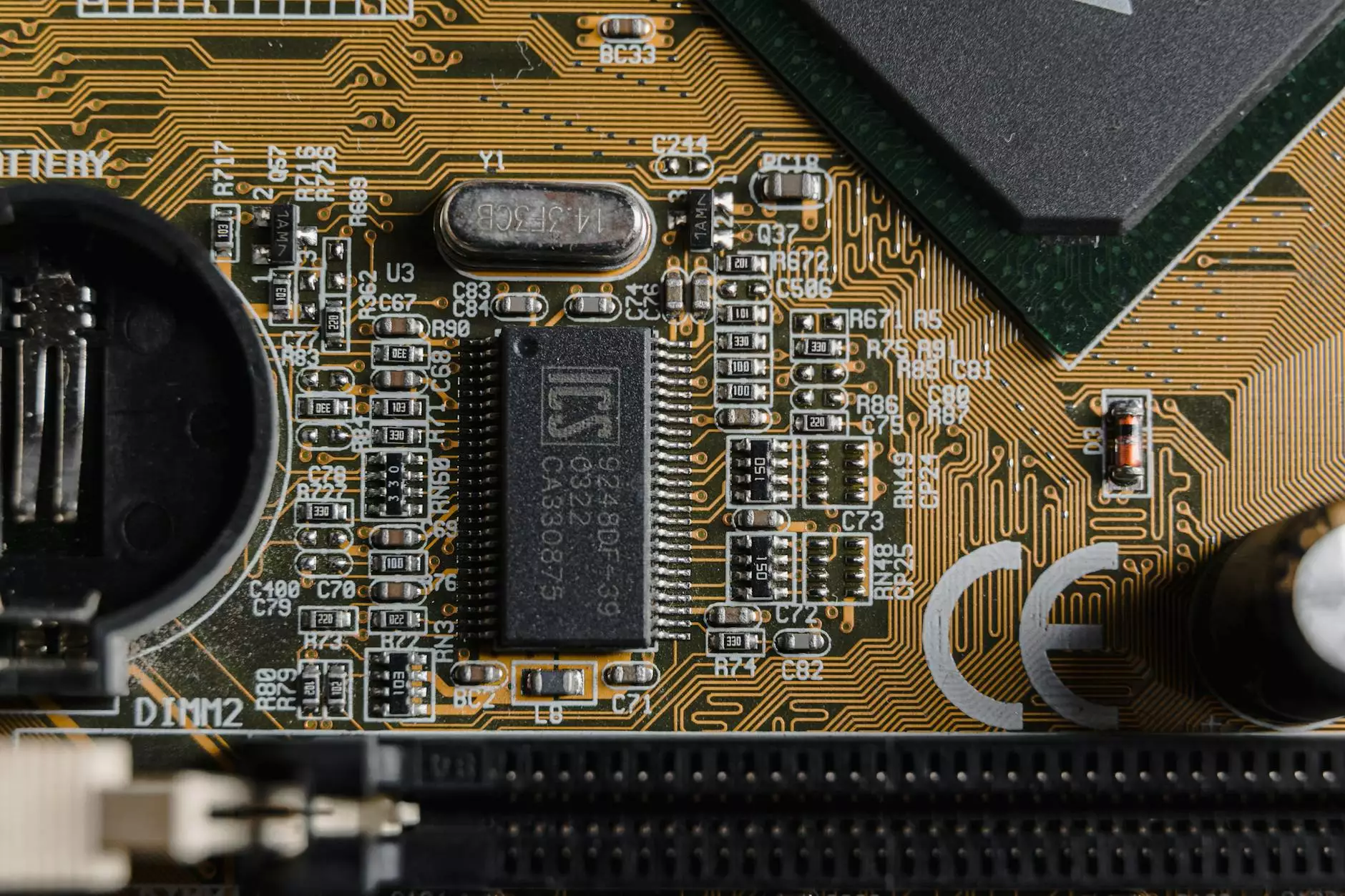

1. Smart Technology

Integrating IoT capabilities enables real-time monitoring and management of label printer applicators, providing insights into operational efficiency and potential maintenance needs.

2. Enhanced User Interfaces

Modern devices often come equipped with intuitive touchscreen interfaces that simplify operation and reduce training time for staff.

3. Eco-Friendly Solutions

Expanding options for biodegradable and recyclable label materials empowers businesses to meet sustainability goals.

Maintenance and Support for Label Printer Applicators

Proper maintenance of your label printer applicator is critical to ensure longevity and optimal performance. Here are some essential maintenance tips:

1. Regular Cleaning

Dust and adhesive residue can accumulate over time, impacting the quality of labels applied. Implement a routine cleaning schedule to maintain peak performance.

2. Software Updates

Keeping your device's software updated is vital to incorporating the latest features and security enhancements.

3. Training Operators

Ensuring that staff are trained appropriately on the use and troubleshooting of the applicator can prevent misuse and reduce downtime.

The Future of Label Printer Applicators

The demand for efficient labeling solutions continues to grow as industries evolve. In the future, we can expect:

- Greater Automation: The trend towards full automation in manufacturing will likely enhance the capabilities of label printer applicators.

- AI Integration: Artificial intelligence may provide predictive analytics for maintenance and operational efficiency.

- Customization: As customers seek unique products, applicators that handle custom labels and unique applications will gain popularity.

Conclusion

As more businesses recognize the advantages of integrating a label printer applicator into their operations, it's clear that these machines will continue to play a pivotal role in the evolution of labeling processes across various sectors. At OmegaBrand.com, we are dedicated to providing top-notch printing services and solutions that meet the diverse needs of our customers. Whether you are in manufacturing, retail, or electronics, investing in a label printer applicator is not just a trend—it's a step toward operational excellence and customer satisfaction.

Get Started with OmegaBrand.com

Ready to improve your labeling processes? Visit OmegaBrand.com to explore our range of label printer applicators, customized solutions, and expert advice to take your business to the next level. Efficiency is just a label away!